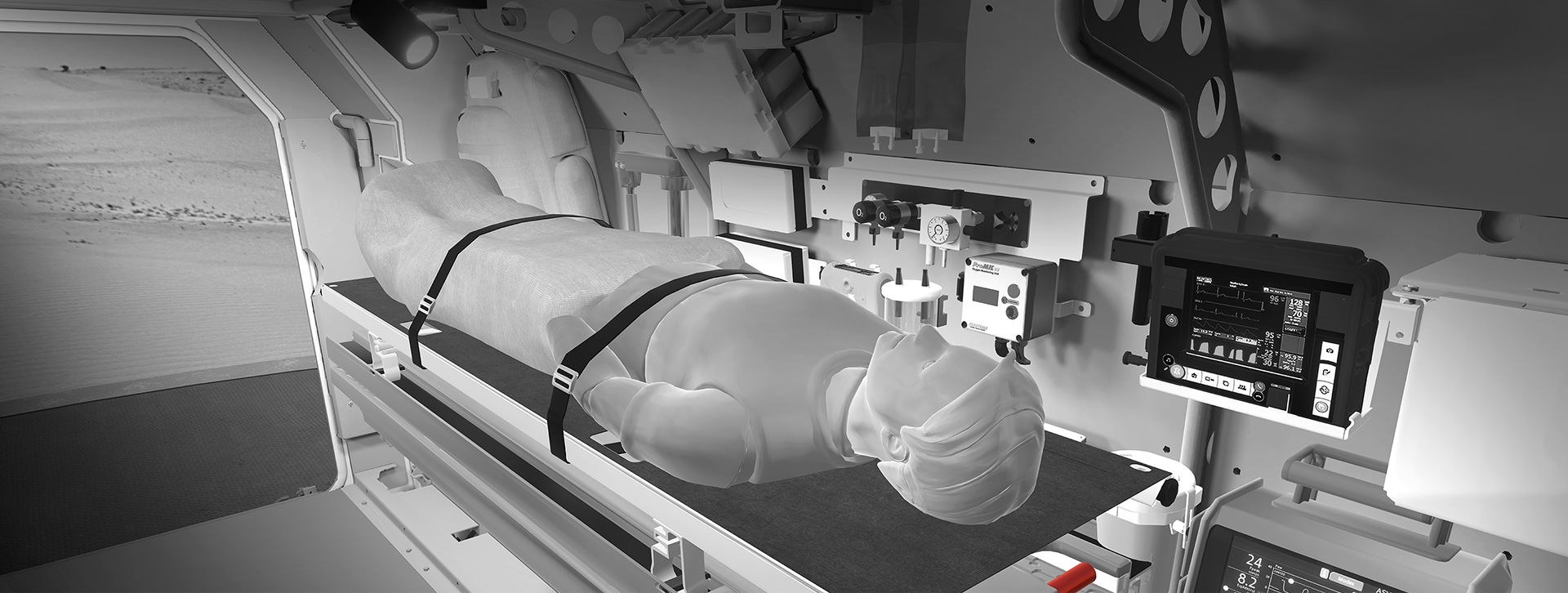

We quickly noticed that requirements for the ambulance stretcher systems were higher in this case than in any other case that we had come up before. Environmental requirements were demanding strong and robust solution. On the other hand limited space in side of vehicle creates need for coefficient of difficulty. Project started out as an ALU – preliminary layout study. In this study we introduced variety of solutions by using existing products from military product family ProMIL as the basis for design, Ari-Matti Vuorenoja, CEO of Frestems tells.

“We quickly noticed that requirements for the ambulance stretcher systems were higher in this case than in any other case that we had come up before”

Together with Hägglunds experts, Frestems’ ProMIL 245 stretcher system was chosen as the best possible option for the case. ProMIL 245 was originally designed for and delivered only to extremely high vehicles to ease the otherwise near-impossible task of lifting stretcher patients from the ground into the vehicle. Unique mechanical design was key element finding best possible choice. ProMIL 245 with modular design was again unbeatable.

ProMIL 245 was originally designed for and delivered only to extremely high vehicles to ease the otherwise near-impossible task of lifting stretcher patients from the ground into the vehicle. In this case, ProMIL 245 mechanism was designed in a way that made stretcher system suitable just for customer’s special needs.

According to Vuorenoja, after the selection, the journey began towards winning the trade. He pinpoints, that close cooperation to tailor the system for BvS10 vehicle interface and also to meet the requirements started already at tender phase.

– The scale of the project demanded a comprehensive plan to manage all the aspects of the project from system safety, risk assessment and quality assurance to product design and ILS (Integrated Logistic Support). For example, the ILS package we delivered was more extensive than before which was a great opportunity to learn BAE Hägglunds’ way of doing, Vuorenoja says.

ProMIL 245 stretcher system turned out to be an excellent choice as it passed flawlessly all the designed tests. Basic series deliveries were made on time and we were acknowledged by both BAE Hägglunds and the end customer. Vuorenoja highlights that customer credited Frestems for an excellent cooperation, design and project management together with the final product. Production for the option systems will be started autumn 2014.

– We also felt that the project was comfortable in every aspect and we enjoy co-operating with Hägglunds employees enjoying great atmosphere there, Vuorenoja says.

Read more about ProMIL 245 advantages at the product page.